What is Orangeburg Sewer Pipe and Where Did it Come From?

This month’s Roto-Rooter Pipeline will touch on the history of Orangeburg sewer lines and how this product came to be.

Older Iowa homes and businesses contain sewer lines that were made of wood fibers and hot tar, known as “Orangeburg”. Orangeburg sewer lines cannot be repaired only replaced. Unfortunately, replacing any sewer line can be costly. And, unlike today’s sewer lines that are made of either cast iron, PVC or HDPE, they can be repaired in most cases. Today’s materials are made to last approximately 75 years.

How did Orangeburg come to be? During the industrial age in the United States, a new type of conduit pipe evolved, made of wood fibers bound together with a water resistant adhesive, and, thereafter, infused with liquefied (hot) coal tar pitch. The first known use of “fiber” pipe was for a water transmission in the mid-1800s: a 1.5-mile pipeline in the Boston area, which stayed in service for 60+ years. Nothing more happened with the commercial manufacturing of this “pipe” until the late 1800s.

During the next 40 years, the fiber conduit business flourished — many new buildings used the flattened (oval-shaped) conduit for running electrical lines throughout floors/walls. Some of the more notable buildings containing miles of the electrical conduit were New York Park Avenue Tower and the Empire State Building … along with other skyscrapers in New York City and other cities. Demand for the conduit pipe rose even higher during World War II due to a shortage of cast iron … for use in constructing armed forces’ airfields and military bases.

In the early years of the 1900s, the market expanded for fiber conduit. Subways were built beneath larger eastern cities; fiber conduit was used for electrical, telephone, telegraph, etc. It was also used to create underground duct banks for electrical, etc. distribution under streets and roads; and along railroads to carry wiring. Orangeburg was later tried by the oil industry (as a “pipe”) to move waste “salt water,” resulting from oil drilling operations, sent cross-country to points of disposal or treatment. It was soon learned that under “pressure” situations the pipe did not hold together … however under “gravity” circumstances, it performed well (setting the stage for its later use as “gravity” sewer pipe … starting in the late 1940s. Early on fiber conduit pipe was called “Alkacid” by the Fiber Conduit Co. of Orangeburg, NY. The oil industry soon stopped using the fiber “Alkacid” pipe, and started using a cement-asbestos pipe.

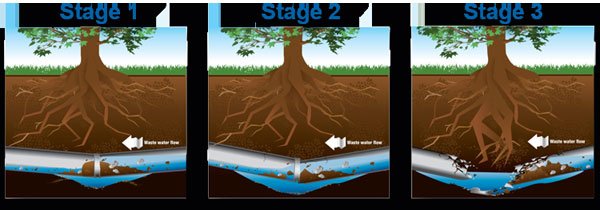

1948 saw the name Fiber Conduit Company changed to the Orangeburg Manufacturing Company. Post-war housing building boom was underway, and the types of pipe available, and affordable, for sewer lines were limited. A heavier-walled and round version of the fiber conduit was developed and sold as “Orangeburg” sewer pipe (in sizes ranging from 2″ to 18″ I. D.). The joints were coupled — utilizing no gaskets, joint sealant, just simple compression, thus making the pipe potentially susceptible to root intrusion. Orangeburg pipe was lightweight, brittle, and it could be cut by hand with a handsaw.

It was recognized early on that Orangeburg pipe had a tendency to deform when subjected to pressure over long periods of time from the soil above. Manufacturers emphasized to properly “bed” the pipe — using soil free of rocks/debris in the trench. (Good bedding did not prevent “deformation” of the pipe by tree roots.) This method is similar to how modern PVC sewer pipe, is bedded.

Orangeburg Before;

Orangeburg After;

Demand for fiber sewer pipe in the 1950s and 1960s skyrocketed! The plant at Orangeburg, N.Y. was expanded several times. At least three other companies (Line Material Company of Barton, WI, and the Brown Company (aka Bermico) of Berlin, NH) also made a similar sewer pipe, but Orangeburg was by far the largest manufacturer.

Canada and England used a similar sewer pipe known in those areas known as “no-corrode” or “black” pipe.

Then, in the late 1960s PVC pipe came along. PVC sewer pipe product was cheaper for sewer line applications. The Orangeburg, New York, plant closed in the fall of 1972. Millions of feet of the fiber electrical conduit are still in service within building structures and under our nation’s streets/roads. A similar amount of the fiber conduit sewer pipe is still in service as home sewer lines, in leach fields, etc., throughout the United States. Right, wrong, or indifferent, fiber conduit pipe became a well used sewer/plumbing pipe. Such pipe was referred to commonly as “Orangeburg” pipe, no matter which company made it.

Based on what has been learned about this pipe material over the past 60-70 years, if you believe this type of pipe is in your sewer system, find out where it is located and what condition it is in, since it has demonstrated to have a limited life expectancy. Orangeburg will deform, losing its circular shape, allowing root intrusion. Tree roots will also wrap themselves around the outside perimeter of the pipe and precipitate the crushing of the pipe. Orangeburg sewer lines also seem to “belly” easier than other type of sewer lines.

On the other hand, for being a “hot tar infused paper tube,” this product hasn’t done so badly.

If you suspect your home or business has an orangeburg sewer line, it is highly advised to it have inspected periodically. These sewer lines have aged and can break down anytime. Call Roto-Rooter Plumbing & Drain Service in the Des Moines and surrounding area at 515-278-5668 or 800-GET-ROTO to schedule an inspection. Ask for Jim. Roto-Rooter can also repair your orangeburg and any other type of sewer line.